Lightweight Manufacturing proudly serving the fabric industry.

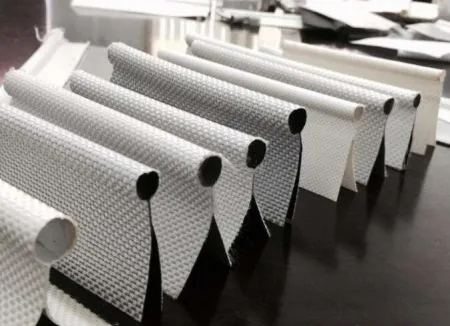

Tensile textile solutions that work.

Architectural quality fabric at your service.

Undoubtedly, Lightweight offers the highest quality fabric panels made with industrial, architectural coated fabrics, advanced laminates, and films requiring heat sealing.

Precise choices for all of your products.

In addition, we dedicate ourselves to providing our clients with innovative, custom, products. Therefore, we offer assistance with fabric selection for projects and free samples to anyone located in the US and Canada.

Leader in keder solutions.

If you’re a manufacturer looking for a wholesale supplier or a rental company needing keder for repairs or alterations, we can help! For example, we distribute a variety of keder products such as sewing, single flag, double flag keder, and keder rails.

Engineering and design services.

Without a doubt, Lightweight specializes in structural engineering and design services for tensioned fabric structures. For instance, we provide services such as certification for fabric structures, engineering drafts and sealed calculations to building code standards.

Lightweight Manufacturing: uncompromising credibility, authenticity and trust.

Undeniably, Lightweight Manufacturing was founded to provide the best service to the fabric structures and tent rental industries with the manufacturing of architectural fabric panels and related engineering services.

Typically, Lightweight works in a subcontractor role, keeping your project confidential and protecting your brand name by not marketing our services using your project without permission.

Therefore, our website provides limited references to the broad range of projects supported. Do not hesitate to contact us with information about your project for consultation.